1.During this section sampling locations and frequency reduced when compared to previous phases. two. Stage III represents that the water system shows dependable under Regulate attainment about such quite a long time interval & Stage III normally operates for just one year once the satisfactory completion of stage II.

The C prerequisites do not have a immediate impact on the product high-quality and it really is an advantage to for each-form as most of Those people assessments as you possibly can while in the factory. To obtain an impact of course of action values, product or service good quality and system ability, these values can be recorded within the manufacturing unit.

The extra risks as a result of swift startup process and insufficient knowledge have to be offset elsewhere. Specifically in the main months, a significant diploma of Command is needed until sufficient practical experience has become obtained. Soon after releasing the water for pharmaceutical purposes, PQ continues till one calendar year of data continues to be acquired or until the unit is decommissioned.

This guarantees that things to do are executed Based on the requirements set in the agreed framework. It is additionally practical to write down simple details of project execution that are not dealt with during the URS. This is able to outline:

Determine the basic necessities for water distribution system component and All round system building

6.2 Significant working parameters needs to be identified. Experiments to the crucial variables really should consist of ailments encompassing higher and reduced functioning boundaries and circumstances (also known as “worst circumstance circumstances”).

The objective of pharmaceutical water system validation all through these 3 phases ought to show that water system is under control and manufacturing the required excellent of water above quite a while interval.

Achieve the information and aggressive edge you'll want to succeed in the pharmaceutical and biopharmaceutical engineering industries and be part of greater than eighteen,000 pharma specialists from all over the world by getting an ISPE Member.

Producing Operations Exactly what are the critical parameters for GMP method validation and How are you going to keep track of and Regulate them?

The sequence of examination performances also must be deemed. The slope with the pipes need to, for example, be measured prior to the distribution pipe is insulated — in the case of the warm distribution system — which regularly happens ahead of the IQ is began as the set up is ready.

Remarks needs to be specified in producing and compiled in one document clarifying who may have commented on what. For fast-monitor initiatives, these approval routines are particularly critical and needs to be recognized firstly of the water system qualification steps challenge. It is also advised that the number of approving parties is retained to the least. The person should really specify which schedule applies to change requests within the venture and from when it's relevant.

Biocidal wavelength: 254 nm; UV dose variables: lamp depth, residence time distribution and water transmittance need to be appropriately measured.

Together with all other onsite qualification routines that needs to be done before beginning PQ, the traditional qualification process may perhaps have to have approximately 4 months. This is why cellular water options aren't usually Utilized in the pharmaceutical industry.

two. It features variety of tests developed as a way here to confirm the steady satisfactory system general performance.

Alana "Honey Boo Boo" Thompson Then & Now!

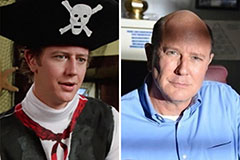

Alana "Honey Boo Boo" Thompson Then & Now! Bug Hall Then & Now!

Bug Hall Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!